What Is RTD Plywood? Key Essentials You Should Know

Published November 26, 2025

Struggling to choose the right materials for your project? With so many options out there, it can feel overwhelming. Plywood remains one of the most versatile and reliable choices for construction and DIY work—but not all plywood performs the same. If you’ve ever wondered what is RTD plywood and whether it’s the right fit for your needs, knowing its unique benefits can help you avoid costly mistakes and ensure your build stands the test of time.

In this article, we’ll explain what RTD plywood is, how it’s made, and its practical uses. You’ll also see how it compares to other plywood types, with tips for selection and installation. By the end, you’ll know when RTD plywood is the right option for your project.

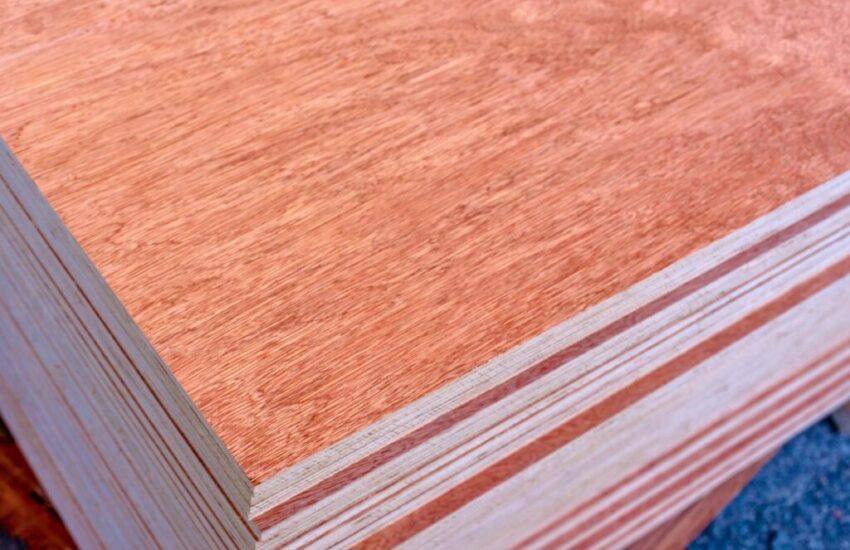

What Is RTD Plywood?

RTD plywood is a type of sheathing known for its consistency and strength. RTD stands for Resistance Temperature Detector. This refers to heat-sensing technology used during manufacturing. The sensors monitor adhesive curing while the plywood is pressed. This ensures even bonding across each panel. It reduces the risk of weak spots or delamination found in traditional plywood.

Standard plywood relies on pressing and glue, while RTD plywood incorporates real-time temperature tracking during manufacturing. This process results in panels with consistent strength and improved durability, guaranteeing uniform quality across every sheet.

What Is RTD Plywood Used For?

Thanks to its verified bond strength and dependable structural performance, RTD plywood is a popular choice for residential and commercial buildings—especially where stability and load support are needed.

Common uses include:

- Structural framing: It serves as a key component in framing systems, providing stability and support.

- Roofing and wall sheathing: RTD panels create a stable surface for roofing and siding and effectively resist moisture. This quality makes them ideal for protecting buildings during construction.

- Subfloors: Because RTD plywood resists moisture, it’s well-suited for subflooring. It provides a solid, even base and helps prevent squeaks and warping over time.

- Exterior walls: Used in exterior wall assemblies, RTD plywood adds shear strength and rigidity to the entire structure.

- Load-bearing uses: RTD plywood works well in applications needing strong support for heavy loads, such as in floor and roof systems. Its verified strength is a major advantage.

Key Features Of RTD Plywood

RTD plywood’s manufacturing process offers several key advantages. These benefits directly improve construction reliability and long-term performance.

Key characteristics and benefits include:

- Moisture resistance: RTD plywood has a superior bonding process. This makes it less susceptible to moisture penetration and delamination. These are common failure points in standard plywood, especially when exposed to humidity or rain.

- Enhanced strength: The adhesive cures consistently, creating a stronger panel. It delivers predictable structural performance. Unlike other wood panels, it has no hidden voids or weak spots.

- Dimensional stability: RTD plywood resists warping, twisting, and swelling. It’s capable of handling changes in temperature and humidity well. This keeps structures straight and sturdy.

- Longevity: RTD plywood is durable and resists environmental factors. This extends the service life of the entire building assembly.

RTD plywood provides an upgrade in both reliability and moisture resistance compared to standard plywood. Consider RTD when your project demands extra durability or will face construction-related moisture exposure.

How RTD Plywood Is Manufactured

RTD plywood starts with stacked wood veneers, laid with alternating grain directions as in standard plywood. The key difference lies in the bonding process, which is precisely controlled to ensure strong panel construction.

During the hot pressing process, Resistance Temperature Detectors take real-time temperature readings inside the panel layers. This ensures the adhesives reach the right temperature for optimal strength. The process eliminates guesswork. It gives each sheet a consistent and fully cured bond. This improved quality control makes RTD plywood reliable and structurally sound.

Pros And Cons Of RTD Plywood

Like any building material, RTD plywood has its own set of advantages and potential drawbacks.

Pros

- Superior moisture resistance: The strong adhesive bond reduces the risk of delamination. It remains intact even under exposure to moisture.

- Exceptional strength and reliability: Consistent manufacturing ensures predictable quality. The panels have dependable structural integrity.

- High durability: It stands up well to the rigors of a job site and contributes to a longer-lasting structure.

- Peace of mind: RTD plywood reduces the risk of material failure. It’s especially reliable for critical structural applications.

Cons

- Cost: RTD plywood is made using advanced technology and strict quality control. This makes it more expensive than standard plywood or OSB.

- Availability: It may not be as widely available as more common sheathing options like CDX plywood or OSB in all locations.

RTD Plywood Vs. Other Plywood Types

- RTD plywood vs. CDX: CDX is a common construction plywood made with C-grade and D-grade veneers and exterior glue. However, it lacks the precision quality of RTD plywood, which provides stronger bonds and better moisture resistance.

- RTD plywood vs. OSB: Oriented Strand Board (OSB) is an engineered wood panel crafted from compressed wood strands. While it’s often cheaper, OSB tends to swell when exposed to moisture, particularly along its edges. In contrast, RTD plywood offers superior dimensional stability, making it a better choice for humid or wet conditions.

- RTD plywood vs. Pressure-treated plywood: Pressure-treated plywood undergoes chemical treatment to resist rot and insects. It works well for ground contact or moist areas. RTD plywood is not rot-resistant but has consistent bonding and a reliable structure.

How To Choose The Right RTD Plywood For Your Project

Choosing the right panel is about more than just selecting RTD. Keep these factors in mind:

- Thickness, grade, and rating: Choose the thickness (e.g., ½”, ⅝”, ¾”) based on structural needs like span ratings for roofing or flooring. The grade reflects face veneer quality, but for sheathing, structural performance matters most.

- Indoor vs. outdoor use: RTD plywood is rated Exposure 1. This means it can handle moisture during construction. However, it’s not meant for permanent, direct weather exposure. Always protect it with siding or roofing.

- Budget considerations: Determine if the added cost of RTD is worth it. For critical areas like roofs or subfloors, it can prevent expensive repairs later. For less critical interior use, standard plywood may be enough.

Installation Tips For RTD Plywood

Proper installation is key to maximizing the performance of RTD plywood.

- Cutting, fastening, and spacing: Use a sharp blade for clean cuts. Follow local building codes for fasteners. Leave a ⅛-inch gap between panel edges to allow for expansion and prevent buckling.

- Avoiding moisture problems: Store panels flat and off the ground before installation, even though they’re moisture-resistant. Install water-resistive barriers over sheathing promptly.

- Safety guidelines: Wear safety glasses, gloves, and a dust mask when cutting. Handle large panels with a partner to prevent injury and damage.

Frequently Asked Questions

Is RTD plywood waterproof?

No. RTD plywood is moisture-resistant but not waterproof. It handles temporary exposure better than standard panels, but it’s not intended for permanent water contact.

Is RTD plywood good for roofing and subfloors?

Yes. Its strength and stability make it a suitable choice for both applications.

Can RTD plywood be used outdoors?

It can be used for exterior sheathing that will be covered by siding or another protective layer. It should not remain permanently exposed.

Does RTD sheathing plywood need special treatment?

No special treatment is required beyond standard protective coverings used in building assemblies.

Is RTD plywood stronger than CDX?

Yes. The manufacturing process of RTD plywood eliminates voids and ensures a consistent bond, giving it more reliable and predictable strength than a typical CDX panel.

Your Takeaway: Making Confident Choices With RTD Plywood

RTD plywood is a significant advancement in wood panel technology. Now that you have a comprehensive understanding of what is RTD plywood, you can make confident decisions about when and where to use it. For demanding applications like subfloors, wall sheathing, and roof decks, RTD plywood offers dependable, long-term performance that helps ensure your project is built on a solid foundation.

If your project calls not only for reliability but also for character and unique visual appeal, consider exploring high-quality reclaimed and specialty wood. Vintage & Specialty Wood offers exceptional materials that bring history, beauty, and craftsmanship to your builds—perfect for projects that deserve something truly distinctive.

Hire The Timber Experts For Your Next Project

Vintage & Specialty Wood should be your source of the highest quality timbers from around the world. When it comes to fabricating and installing reclaimed wood or specialty wood products in your home, we don’t cut corners. We offer many reclaimed wood and specialty wood products such as Douglas Fir, white oak, and much more. We also offer timber framing and wood flooring services as well. Contact our team today to speak to a timber expert about what Vintage & Specialty Wood can do for you.

This Blog Is Fact Checked

This content has undergone meticulous fact-checking by our team of internal experts. Gain a deeper understanding of the high editorial standards we uphold on our website here.

About The Author

Experience, exploration, and knowledge are the hallmarks of writer Rei Bayucca. Her dedication to crafting articles that both inspire and educate will leave you thinking long after you’ve finished reading.